Abstract

Goal

The DiscoveryMat software predicts the chemical composition of metallic alloys. The proposed system is:

Its portability enables you to bring it everywhere with you, even onsite! You do not have to dismantle the part that needs to be analyzed. One of the main fields of application is Conservation and Restoration.

Proposed approach

The idea is to put a drop of liquid on the surface of the material whose alloy we are trying to identify. A slight corrosion sets in over minutes. The induced electric field is measured over time. A time series of 15 minutes is collected, at intervals of 1 second between electric potential measurements.

An artificial intelligence algorithm then predicts the composition of the alloy. This prediction is based among other things on a labeled dataset, constituted of around 123 materials with different compositions. To improve the efficiency of the method, we use not one, not three time series generated with three different drops of liquid. The liquids used are:

Validation

This innovative approach proposed by DiscoveryMat has been thoroughly validated on clockwatch collections from the reknown International Horology Museum (MIH) of La Chaux-de-Fonds, Switzerland. To compare the quality of the predictions of the DiscoveryMat approach with the current state-of-the-art, X-Ray fluorescence was also used to establish the composition of alloys.

More in details: this analytical tool has been tested on a collection of historic objects from the International Museum of Horology, La Chaux-de-Fonds, CH. We have checked the portability of the measuring instrument and its quasi-non-invasive character (polishing of the metal is required but is limited - 4000 grit a few seconds - to remove the thin oxide layer). As the copper alloy materials specific to this horological domain were not yet covered by the existing database, the tool could only give suggestions of compositions. In the case where the metal analysed had a composition close to a material of the database, the algorithm of comparison / classification gave a good match. In the other cases, the elements present in the metal were given as well as approximate compositions. The precise elementary analysis of these materials with X-Ray fluorescence enabled us to insert these new materials in our database to enrich it. Currently the database contains 123 materials with known composition and electrochemical behaviour.

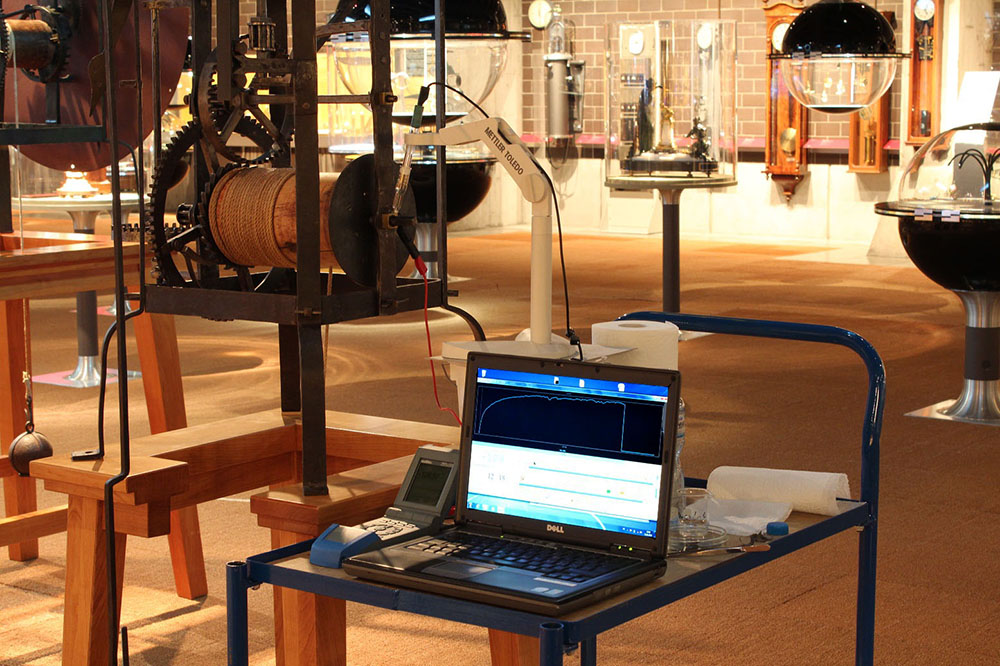

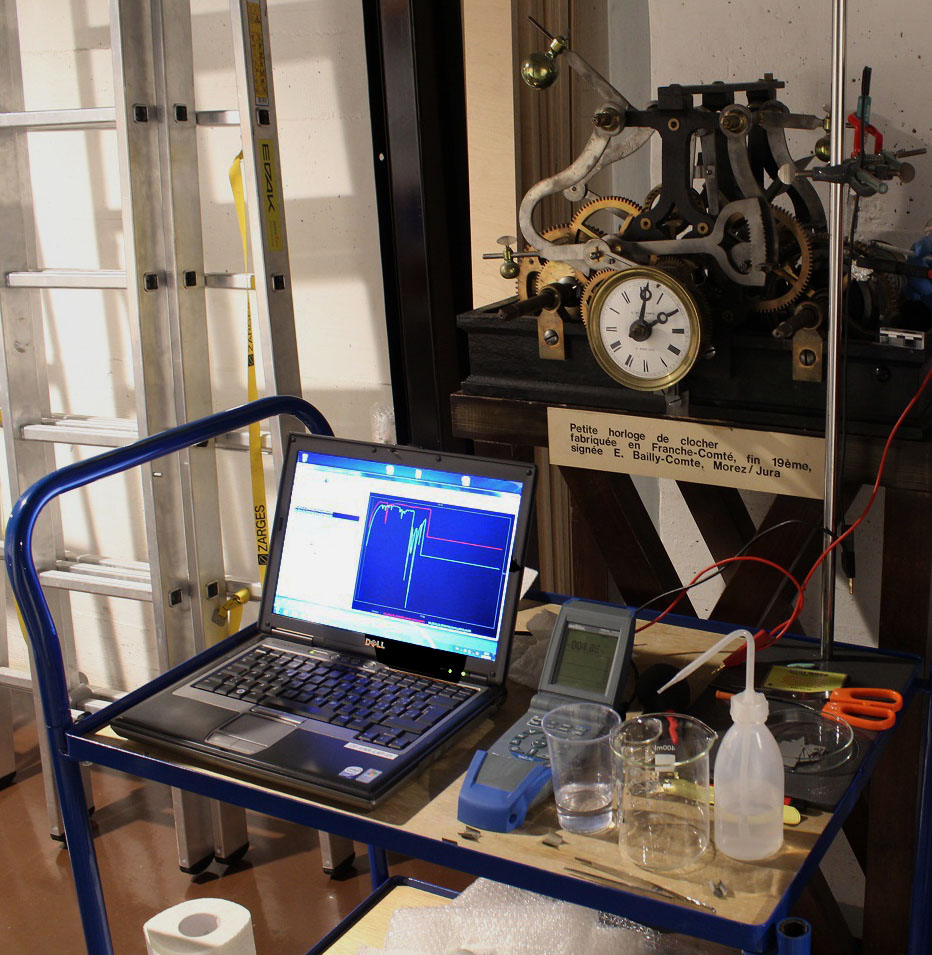

Live shots

Figure : In-situ measurement in the exhibition area of the MIH on a 17th century tower clock of the museum collection:

Hardware required

The multimeter measures electrical potential between the metal tested (of unknown composition) and a measuring system constituted of an Ag-AgCl reference electrode (RE) extended by a junction protection tube (JPT). The automatic collection of data requires the use of a volmetre usb-connected to DiscoveryMat software. The quality of the measurement depends on the surface preparation of the metal studied. These measures should be performed on a conductive metallic surface. That is why the metal should be cleaned of any oxide layer.

Software

The DiscoveryMat software allows you to benefit from the entire analysis pipeline for alloy prediction. That software is provided free of charge.